![Cedarshed studio 12x6 shed [st126]](https://i0.wp.com/www.shednation.com/oscthumb.php?src=/images/cedarshed/cedarshed-studio-shed-st96-1.jpg&w=1500&h=1220&f=jpg&q=95&hash=a1b196bdc5513eb64d7a831305149a4c) www.shednation.com

www.shednation.com Opening: The Allure of a DIY Shed

Sheds are incredibly versatile structures. Whether you need extra storage space for gardening tools, a dedicated workshop, or even a backyard getaway, building your own shed offers numerous benefits. Not only can you customize the design to perfectly fit your needs and available space, but you can also save money compared to purchasing a pre-built shed. This guide will walk you through the process of building a simple shed from start to finish.

Step 1: Planning and Preparation

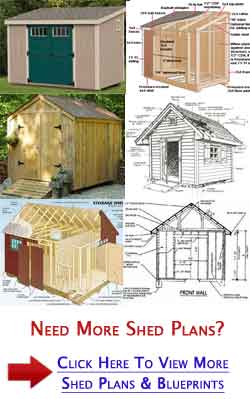

Building a shed requires careful planning. Here's what you need to do: Choose a Design: Research different shed designs online or in books. Consider the size, shape, roof style, and door placement that best suits your needs and backyard layout. Look for free or paid shed plans that include detailed instructions and material lists. Check Local Building Codes: Before you start building, contact your local building department to inquire about permits and zoning regulations. Ensure your shed design complies with all applicable codes. Create a Material List: Based on your chosen plan, create a comprehensive list of all the lumber, hardware, roofing materials, and other supplies you'll need. Accurately estimate the quantities to avoid running out mid-project. Gather Your Tools: Assemble all the necessary tools, including a circular saw, drill, level, measuring tape, hammer, safety glasses, gloves, and a square. Consider renting or borrowing any specialized tools you don't already own. Prepare the Site: Choose a level location for your shed. Clear the area of any vegetation, rocks, or debris. Consider adding a gravel base for drainage and stability.

Step 2: Building the Foundation

A solid foundation is crucial for a long-lasting shed. There are several foundation options, including: Gravel Pad: A simple and cost-effective option for smaller sheds. Level the ground and spread a thick layer of gravel, compacting it thoroughly. Concrete Blocks: Place concrete blocks on leveled ground and use shims to ensure they are level. This method provides a slightly raised foundation. Concrete Slab: The most durable option, but also the most labor-intensive. Pour a concrete slab according to your shed plan's specifications. This requires forming, reinforcing with rebar, and allowing the concrete to cure. For this guide, we'll assume you're using concrete blocks. Ensure the blocks are properly spaced and level before proceeding.

Step 3: Framing the Floor

The floor frame provides the base for the shed's walls and roof. Cut the Lumber: Cut the floor joists and perimeter framing members to the dimensions specified in your plans. Assemble the Frame: Using screws or nails, assemble the floor frame on top of the concrete blocks. Ensure the frame is square and level. Install Floor Joists: Space the floor joists evenly within the perimeter frame, according to your plans. Secure them with screws or nails. Attach the Subfloor: Lay down the subfloor (typically plywood or OSB) on top of the floor joists. Secure it with screws, leaving a small gap between the sheets.

Step 4: Framing the Walls

The walls provide structural support and define the shed's shape. Cut the Lumber: Cut the wall studs, top plates, and bottom plates to the dimensions specified in your plans. Assemble the Wall Frames: Lay the top and bottom plates parallel to each other and position the studs between them, spacing them according to your plans (typically 16 inches or 24 inches on center). Secure the studs to the plates with screws or nails. Frame the door and window openings as specified in your plans. Raise the Walls: Carefully lift each wall frame and position it on the floor frame. Ensure the walls are plumb (vertically straight) and square. Secure the Walls: Secure the walls to the floor frame and to each other using screws or nails. Use temporary braces to hold the walls in place until they are fully secured.

Step 5: Framing the Roof

The roof protects the shed from the elements. Choose a Roof Style: Common roof styles include gable (A-frame), shed (single slope), and hip. Select a style that suits your aesthetic preferences and skill level. Cut the Rafters or Trusses: Cut the rafters or trusses according to your plans. Accurate measurements are crucial for a properly supported roof. Install the Rafters or Trusses: Attach the rafters or trusses to the top plates of the walls, ensuring they are properly spaced and secured. Use metal hurricane ties for added strength. Sheathe the Roof: Cover the rafters or trusses with plywood or OSB sheathing. Secure the sheathing with screws or nails.

Step 6: Installing Roofing and Siding

Roofing and siding protect the shed from the weather and give it a finished look. Install Roofing Underlayment: Cover the roof sheathing with roofing underlayment to provide a waterproof barrier. Install Roofing Material: Install your chosen roofing material (e.g., asphalt shingles, metal roofing) according to the manufacturer's instructions. Overlap the materials properly to prevent leaks. Install Siding: Attach the siding to the exterior walls, overlapping each course properly. Use appropriate fasteners for the siding material you choose (e.g., wood siding, vinyl siding, metal siding).

Step 7: Installing Doors and Windows

Doors and windows provide access and light to the shed. Frame the Openings: Ensure the door and window openings are properly framed and level. Install the Doors and Windows: Install the doors and windows according to the manufacturer's instructions. Use shims to ensure they are plumb and level. Trim the Openings: Add trim around the doors and windows to conceal any gaps and provide a finished look.

Step 8: Finishing Touches

Complete the shed with these final steps: Install Interior Finishing: Add shelving, workbenches, or other interior features to customize the shed to your needs. Paint or Stain: Paint or stain the exterior of the shed to protect it from the elements and enhance its appearance. Add Hardware: Install door handles, locks, and other hardware. Landscaping: Add landscaping around the shed to blend it into your backyard.

Conclusion: Enjoy Your New Shed!

Building a shed is a rewarding project that can provide years of valuable storage or workspace. By following these steps and taking your time, you can create a functional and attractive addition to your property. Remember to always prioritize safety and consult with professionals if you have any doubts about any part of the construction process. Now, step back and admire your handiwork – you've built a shed!

Dcor Design Pracchia 7 X 10 Wooden Storage Shed

www.wayfair.co.uk

www.wayfair.co.uk Cedarshed Studio 12x6 Shed [st126]

![Cedarshed studio 12x6 shed [st126]](https://i0.wp.com/www.shednation.com/oscthumb.php?src=/images/cedarshed/cedarshed-studio-shed-st96-1.jpg&w=1500&h=1220&f=jpg&q=95&hash=a1b196bdc5513eb64d7a831305149a4c) www.shednation.com

www.shednation.com Little Cottage 12 X 10 Ft. Classic Wood Cottage Panelized Storage Shed

www.walmart.com

www.walmart.com  ar.inspiredpencil.com

ar.inspiredpencil.com  pixabay.com

pixabay.com  ar.inspiredpencil.com

ar.inspiredpencil.com  www.licious.in

www.licious.in  www.wholesomeyum.com

www.wholesomeyum.com  therealfooddietitians.com

therealfooddietitians.com  www.yardcraft.com

www.yardcraft.com  decorativewooden.blogspot.com

decorativewooden.blogspot.com  unsplash.com ```html

unsplash.com ```html  unsplash.com

unsplash.com  ar.inspiredpencil.com

ar.inspiredpencil.com  www.beachybarns.com ```html

www.beachybarns.com ```html  countrytymesheds.com

countrytymesheds.com  uk.pinterest.com

uk.pinterest.com  myoutdoorplans.com

myoutdoorplans.com  nellisab.blogspot.com

nellisab.blogspot.com